The application field of aluminum alloy pipes is still relatively common, especially in household appliances, but many household appliances also use copper. Relatively speaking, the advantages of aluminum alloy pipes are greater. People who choose aluminum tubes will be the majority. At this time, some people say that there are aluminum alloy tubes, seamless aluminum tubes and seamed aluminum tubes. What is the difference between them?

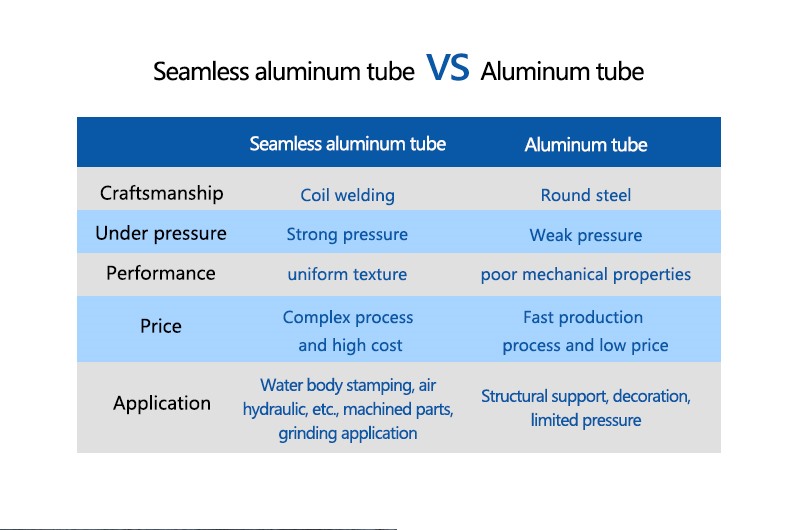

The seamless aluminum tube has better pressure bearing than the seamed aluminum tube. The seamless aluminum tube has a relatively uniform texture. The chemical composition of the welded tube will be burned in a small amount in the welded part, so the mechanical properties are slightly worse but not very different. It is recommended to use seamless aluminum tube if it is used for elbow. Welded pipes are prone to cracking. There is no problem if the bending radius is relatively large. The seamless aluminum tube is formed by perforation extrusion, while the conventional aluminum tube is generally extruded by a combined die. In the production, the extrusion process of short rod, high temperature and slow speed is used, especially when the "three temperatures" are to be well controlled.

The processing methods of aluminum ingots for seamless aluminum tube and seam aluminum tube are different. seamless aluminum tube adopts surface turning, and seam aluminum tube adopts non-oxidized skin rolling.

In terms of mechanical properties, seamless aluminum tube products have uniform metal flow at the beginning and end, high dimensional accuracy, good fatigue resistance, consistent mechanical properties, and no layered structure. The metal flow at the head and tail of the seamed aluminum pipe product cannot be uniform, the mechanical properties are inconsistent, and the layered structure is prone to appear. On the whole, it is better to choose seamless aluminum tube, but it is also necessary to determine the choice according to your own situation.