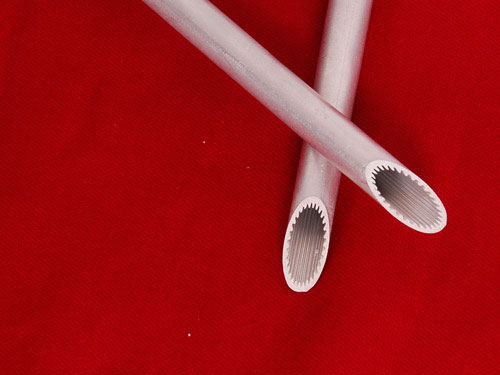

The former is made by cutting the inner surface of the pipe with a superhard turning tool, while the latter is made by cold drawing with a specially shaped tool.The internal thread aluminized tube is patented by American Barger Company, and the geometry of the thread is determined after years of experiments to prevent the tube from overheating under high thermal load, taking into account the fluid friction resistance and the effect on the tube strength.Is the sectional drawing of single-head thread and two kinds of multi-head pipe.

The inner grooved aluminum tube is mainly used for heat exchange of air conditioners. Compared with the light tube, it has a larger inner surface area, which is beneficial to heat exchange when coolant flows in the tube.Therefore, in view of the good heat exchange performance of the inner thread alloy aluminum tube, it will be more and more popular.The most basic method of forming the inner thread is to increase the wall thickness by reducing, while producing the inner thread along the direction of the thread placed on the inner core of the tube during the process.Moreover, the pipe diameter reduction has been greatly improved.