The technical problem to be solved by the utility model is: based on the above-mentioned problems, a replacement for the extruded harmonica tube is provided. High frequency welded rectangular aluminum tubing for intercooler has higher heat dissipation efficiency and better effect than the extruded harmonica tube, and has high production efficiency, energy saving and simple process.

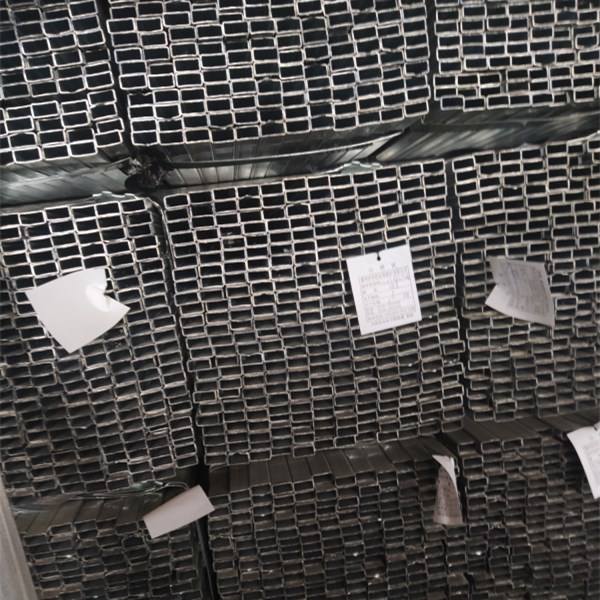

The technical solution adopted by the utility model to solve its technical problems is: a high frequency welded rectangular aluminum tubing for intercooler, including a heat dissipating aluminum tube and inner fins, and the surface of the heat dissipating aluminum tube and / or inner fins has In the compound brazing layer, the inner fins are located in the heat dissipation aluminum tube, and the inner fins and the heat dissipation aluminum tube are integrated into one by a compound brazing layer, and the inner fins are 6mm.Further, the wall thickness of the heat dissipation aluminum tube is O. 3 ~ O. 6mm. Compared with extruded harmonica aluminum tube products, under the same technical requirements, the wall thickness of the heat dissipation aluminum tube is O. 3 ~ O. 6mm, lighter than the extruded harmonica tube, and saves 20 ~ 30% of raw materials.

Compared with the extruded harmonica aluminum tube, high frequency welded rectangular aluminum tubing for intercooler has the same application technical requirements: the product has 20 ~ 30% saving of raw materials, so the weight is lighter than the extruded harmonica tube; the production efficiency is high (50 ~ 70m / min) Therefore, the power consumption is low, and the surface of the produced product has brazed composite materials. No brazing material needs to be added in the subsequent overall brazing process, which makes the subsequent production process simple.

In addition, the inner fin of inside high frequency welded rectangular aluminum tubing for intercooler of the present invention can be designed into various sizes of absorption area according to requirements. The large area of heat absorption can greatly improve the heat exchange effect of the intercooler, It has higher heat dissipation efficiency and better effect than the existing extruded harmonica tube.