In order to achieve the above purpose, the utility model is realized through the following technical solutions:

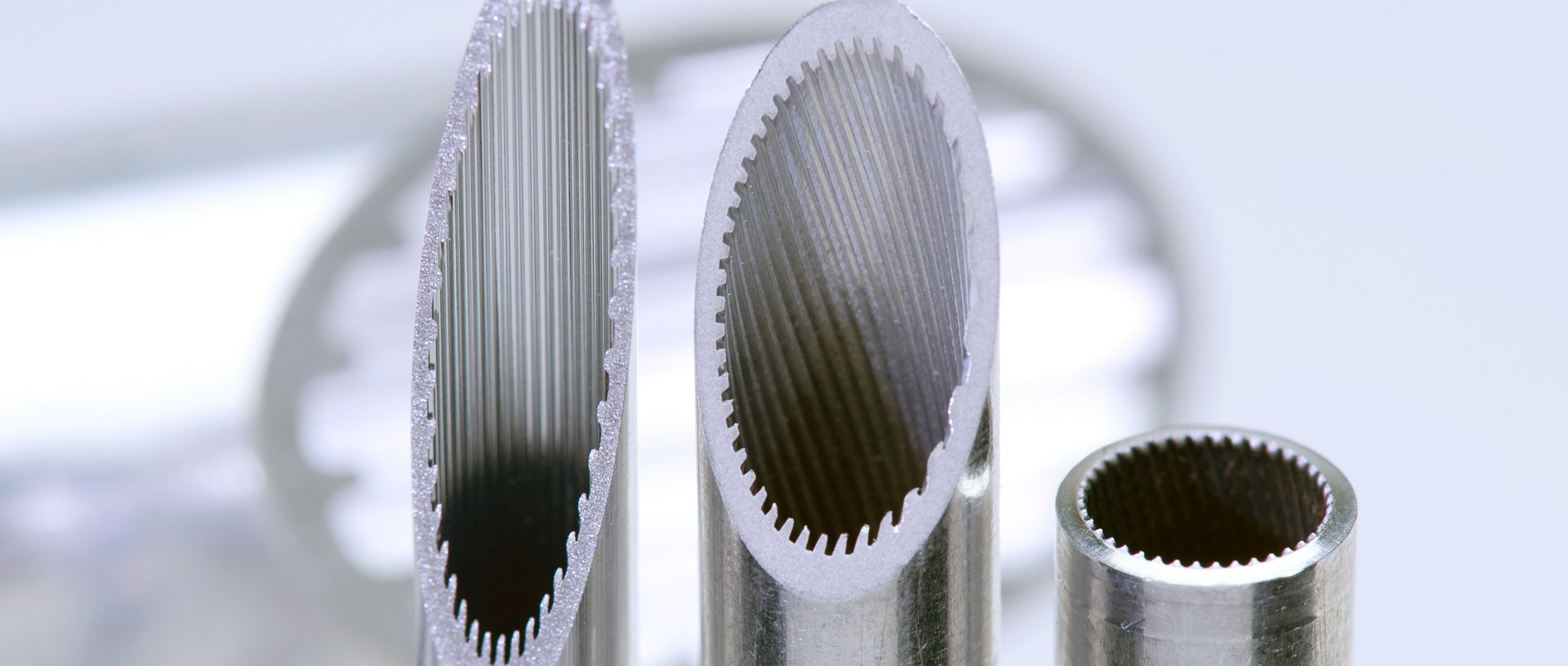

A composite inner grooved aluminum tube, characterized in that the composite internally toothed aluminum tube includes an outer layer aluminum tube, a middle layer aluminum tube and an inner layer aluminum tube, and the inner side of the outer layer aluminum tube, middle layer aluminum tube and inner layer aluminum tube At least one convex strip is provided on the surface, the convex strips are evenly spaced along the inside of the aluminum tube, a groove is provided between the convex strip and the convex strip, and three metal separators are provided in the inner aluminum tube. The three metal partitions are triangular, and the three corners are fixedly supported on the inner side wall of the inner aluminum tube.

It can be seen from the above technical solutions that the utility model is provided with at least one convex strip on the inner surface of the outer aluminum tube, the middle aluminum tube and the inner aluminum tube. The convex strips are evenly spaced along the inside of the aluminum tube. There are grooves between the bars, so that the fluid can fill the entire channel through the grooves, increasing the contact area of the fluid and the aluminum tube wall, and improving the heat dissipation effect; at the same time, there are three metal partitions and three metal partitions in the inner aluminum tube The plate is triangular, and the three corners are fixedly supported on the inner side wall of the inner aluminum tube, forming a multi-channel structure, increasing the contact area of the fluid and the metal separator, improving the heat dissipation effect, and the triangular structure greatly improves its impact resistance Performance, which prolongs the life of the composite inner grooved aluminum tube; the structure of the three-layer aluminum tube also increases the mechanical strength of the aluminum tube.