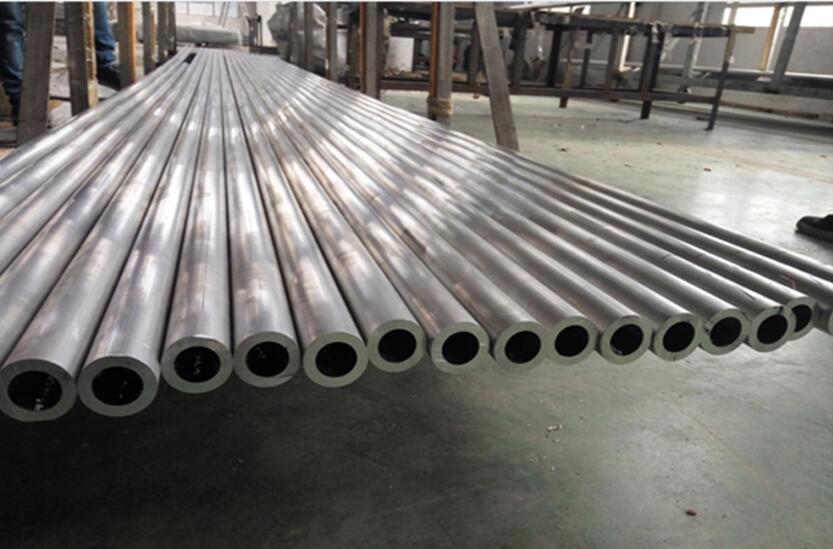

The energy-saving aluminum row tube is made of aluminum alloy with strong anti-corrosion ability, and the surface is anodized. The aluminum row structure is designed as a fin and tube integral die-casting. The tube diameter is Ø25, Ø28, Ø32 and other specifications. The tube has internal parallel teeth. Multiple fin tubes are installed in parallel and welded by elbows to form a large-area aluminum row.

The special structure increases the internal and external surface area and at the same time increases the compressive strength. When leaving the factory, it has undergone 2.5MP air-tightness inspection and 4.5MP pressure life test, surface strengthening treatment, corrosion resistance, and extended service life.

energy-saving aluminum row tube is mainly used in the refrigeration system of cold storage at 10℃ to -45℃. It is an ideal evaporator for freezing and cold storage of various foods. The heat transfer coefficient of aluminum tube is K≈9~14w/m2 ℃ at -40℃~0℃ evaporation temperature, and the heat transfer coefficient of steel tube is K≈8~13w/m2 at -40℃~0℃ evaporation temperature. ℃, for this same cold storage (under the same load), the evaporation area of the energy-saving aluminum row tube is smaller than that of the steel platoon. In addition, from the perspective of comprehensive costs such as aluminum material cost and advanced die-casting technology, the unit area price of aluminum platoon is higher than that of steel platoon but the cost is lower.