Technical difficulties

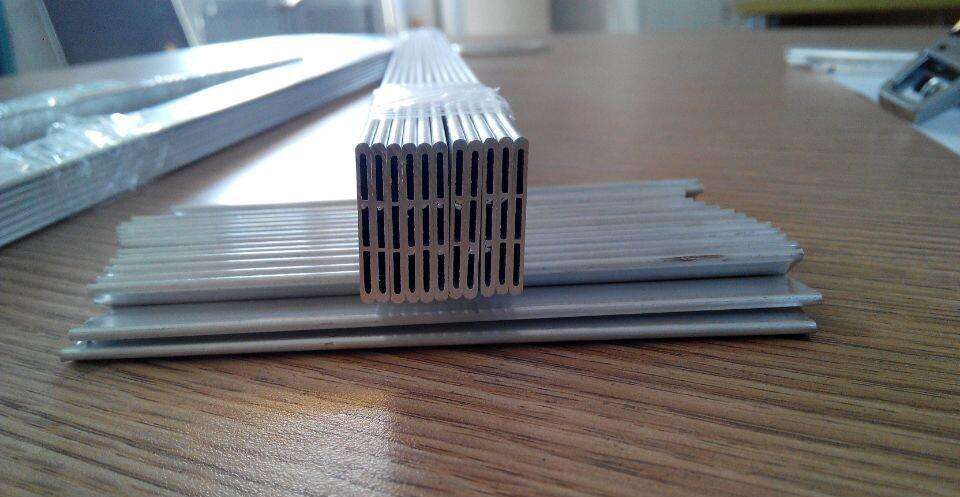

The technical difficulties of aluminum alloy harmonica shaped tube production are as follows:

(1) The aluminum alloy harmonica shaped tube has a thin wall and a large number of holes, which is difficult to form by extrusion. The 25 channels should be relatively closed, the welded microstructure should be free of defects, not cracked during cold deformation, and able to withstand burst pressures greater than 8MPa.

(2) The densely-cavity cavity of the product has a small internal cavity area, the main distribution of the extrusion mold shunt cavity must be reasonable, and the stability of the mold core must be strong. Molds designed by traditional methods cannot produce qualified products, so we must have new ideas in design.

(3) To produce high-standard aluminum alloy harmonica shaped tube molds, the manufacturing accuracy is high. The error of 25 molds relative to the mold center is small.

Production process

The production process of the aluminum alloy harmonica shaped tube is gold smelting, special production, heating, extrusion, stretching, cutting scale → shaping correction → cutting scale → inspection and acceptance library.