Compared with ordinary 3003 alloy constituent elements, the content of Mn and impurity elements Si, Fe and Cu in long-life alloy 3026 is significantly reduced. Theoretical studies have shown that reducing the content of impurity elements can significantly improve the corrosion resistance of the alloy, but the strength of the material is reduced, that is, there is a contradiction between strength and corrosion resistance; and 3003+Zn is a thermal sprayed zinc layer on the surface of 3003 alloy, and the composition is similar to that of 3003 It is basically the same, while maintaining the strength of the material while improving the anti-corrosion performance.

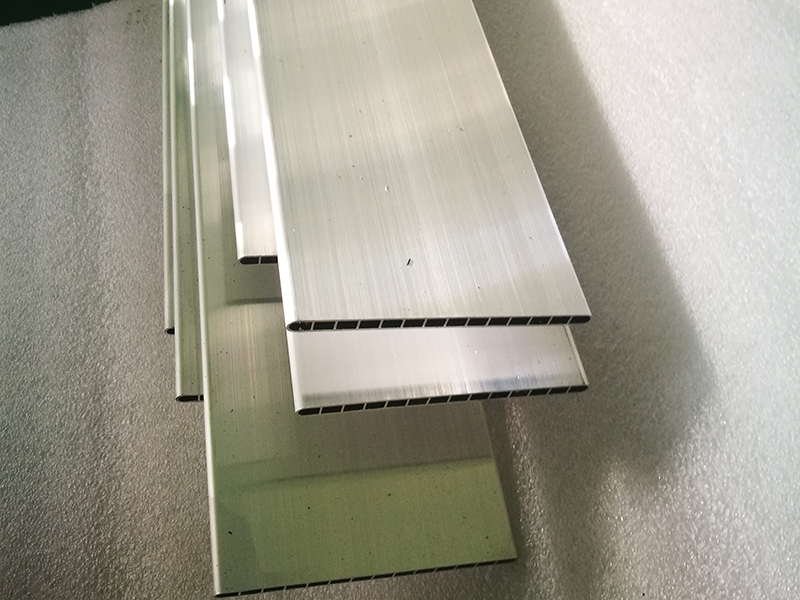

Comparative analysis of the reliability of 3003, 3003+Zn, 3026 Air conditioning heat exchanger aluminium tube materials by SWAAT salt spray test and acetic acid seawater immersion test. Compared with 3003 aluminum alloy, 3003+Zn has better anti-corrosion performance, which is comparable to long-life aluminum alloy 3026. Close. Therefore, the excellent corrosion resistance and cost advantage of 3003+Zn aluminum alloy will have a good application prospect in the air conditioning and refrigeration industry. In addition, under the background of scarcity of copper resources and rising prices, my country's competitiveness in the international refrigeration industry is constrained. Therefore, "aluminum instead of copper" is of great significance and will surely become a direction for the development of the air-conditioning and refrigeration industry. "Aluminum instead of copper" has obvious application advantages in the air-conditioning and refrigeration industry, and has also become a hot spot in the industry's technology development.