6082 aluminum rod is a heat-treated reinforced alloy, which has good formability, weldability, machinability, and moderate strength. It can maintain good operability after annealing, and is mainly used in mechanical structure. This alloy has similar but not identical mechanical properties to alloy 6061, and its T6 temper has higher mechanical properties.

6082 aluminum sheet is a very common alloy product in Europe, and also has a high application in the United States, suitable for processing raw materials, seamless aluminum tubes, structural profiles and customized profiles. 6082 aluminum strip usually has good processing characteristics and good anode reactivity. Commonly used anode reaction methods include removal of impurities, removal of impurities and dyeing, coating, etc.

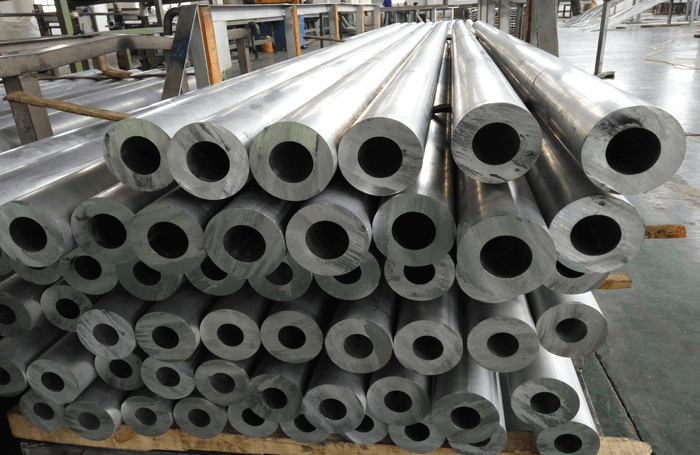

6082 aluminum tube is mainly used for building materials, vehicles, furniture, ships, home appliances, cameras, wires, tennis rackets, etc.

Other uses of 6082 aluminum alloy:

Aviation fixtures, trucks, tower buildings, boats, pipes and other architectural applications requiring strength, weldability and corrosion resistance such as aircraft parts, camera lenses, couplers, marine accessories and hardware, electronics Fittings and joints, decorative or various hardware, hinge heads, magnetic heads, brake pistons, hydraulic pistons, electrical accessories, valves and valve parts, the representative uses of Jinguang aluminum alloys include aerospace fixtures, electrical fixtures, communication fields, and also Widely used in automated mechanical parts, precision machining, mold manufacturing, electronics and precision instruments, SMT, PC board solder carriers, etc.

6082 aluminum alloy chemical composition:

Si: 0.7~1.3

Fe: 0.50

Cu: 0.10

Mn: 0.40~1.0

Mg: 0.6~1.2

Cr: 0.25

Zn: 0.20

Ti: 0.10

Al: margin

Mechanical properties:

Tensile strength σb (MPa): ≥310

Conditional yield strength σ0.2 (MPa): ≥260

Elongation δ10 (%): ≥10

Note: Longitudinal mechanical properties of profiles at room temperature