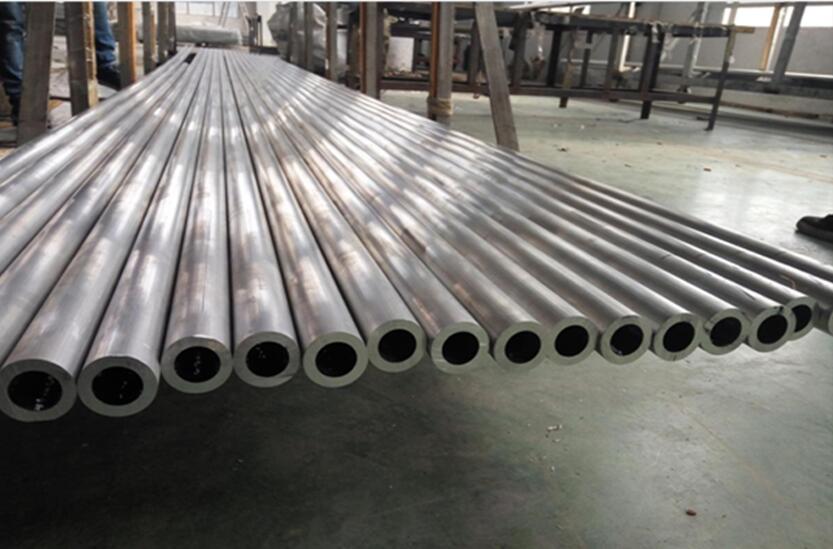

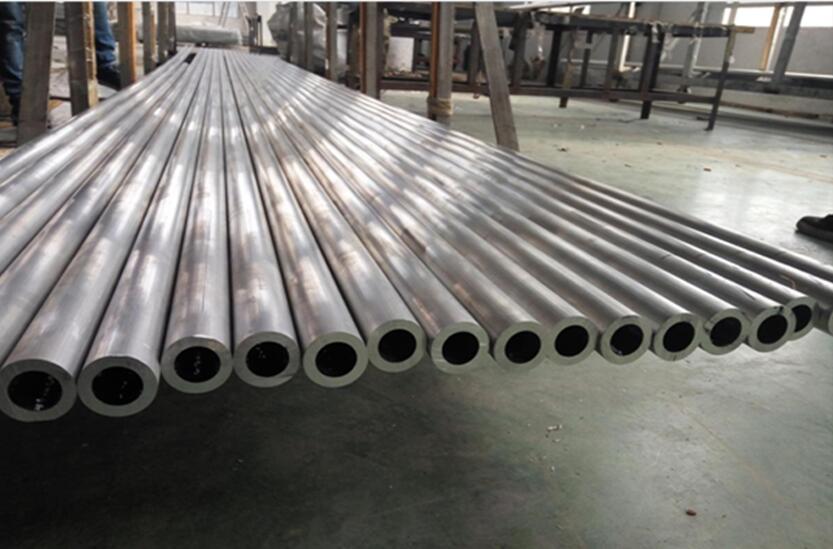

According to the processing method, precision aluminum tubes are divided into: cold-drawn precision drawn precision aluminum tubes, rolled aluminum tubes, and welded tubes. Among them, the precision, surface quality and mechanical properties of the cold-drawn aluminum tube are good. 1 Cold-drawn 6061 fine-drawn precision aluminum tube: The raw material is extruded aluminum tube and rolled aluminum tube. The aluminum tube processed by this processing method: high precision, smooth inner and outer surfaces, and mechanical properties among the three. Therefore, it is widely used in all walks of life. In modern industry, many products use cold-drawn precision drawn precision aluminum tubes, such as oil pipelines for automobiles, aerospace, laser faxes, photosensitive drums in printers, aluminum tubes for magnetic rollers, etc. For precision turning parts, in order to reduce The turning allowance improves the yield, and the 6061 cold-drawn aluminum pipe is also attracting attention and use.

6061 seamless aluminum tube pipe is mainly used in the chemical, petroleum, thermal, boiler, mechanical hydraulic and other industries. It is a large-diameter aluminum pipe with an outer diameter greater than 1020mm. Large-caliber aluminum pipes are characterized by larger diameters and thicker walls. Especially for corrosion-resistant, anti-extrusion oil well pipes, high-quality petroleum cracking pipes, and Q345B aluminum pipes, the demand is relatively large.