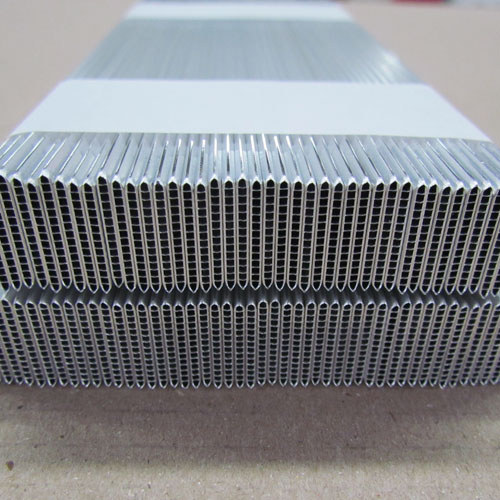

Main alloys: 1 series 1100 etc., 3 series 3003 etc. 9153A

Specifications: The widest aluminum flat tube is 230mm-240mm, depending on the thickness

1) Width 45mm, 5mm thick, wall thickness can be 0.3-0.6mm, thickness tolerance can be 0.05mm

2) 45-125mm wide, 6-20mm thick, wall thickness 0.8-2.5mm, thickness tolerance 0.1-0.2mm

3) More than 125mm wide, wall thickness is 1.2-3mm, thickness tolerance is 0.2mm

Main production process of 1100 3003 Aluminum alloy hot extruded micro-channel precision tube:

Aluminum rod heating extrusion --- zinc spraying --- rewinding --- flaw detection --- plastic cutting --- inspection packaging

Technical features of 1100 3003 Aluminum alloy hot extruded micro-channel precision tube

High-quality cast rod: micro-channel flat tube aluminum rod filter 40 mesh + H0.09 ~ 0.13, and generally 20 mesh + 0.2

High requirements for zinc spraying: the amount of zinc layer is 6-8g / ㎡, but the general spraying fluctuations are large

Online Flaw Detection: Requires Online Flaw Detection

Large extrusion ratio: extrusion ratio is greater than 427, which is more than 8 times higher than conventional extrusion ratio (50)

Ultra-high dimensional accuracy: The accuracy requirement is ± 0.03, which is more than 8 times higher than the international high-precision level

High air tightness requirements: Product defects are measured by PPM, which is 200 times higher than traditional% requirements

1100 3003 Aluminum alloy hot extruded micro-channel precision tube are mainly used in:

Appliance refrigeration

Freezer

Car refrigeration

Base station cooling (Huawei 5G base station application)