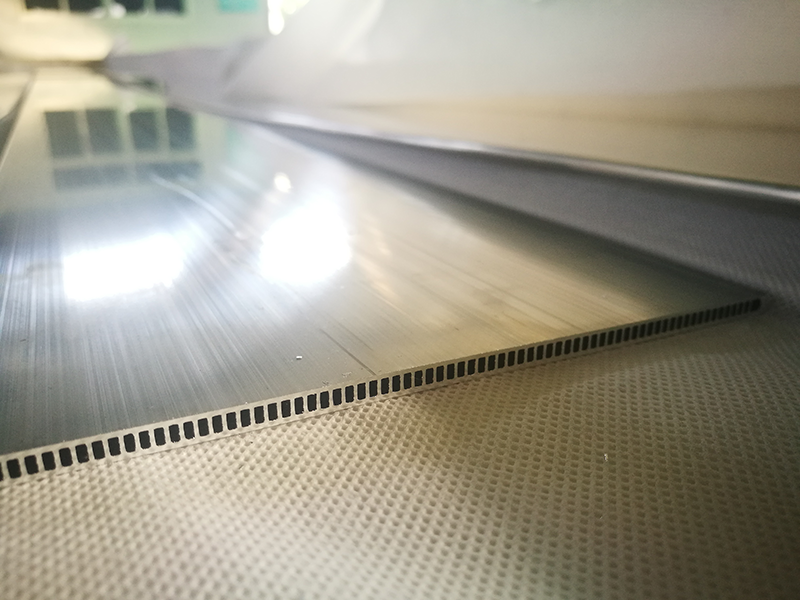

International high-end products: such as 1050 H12 Zinc sprayed micro-channel aluminum tubes used in heat exchangers for automobiles, commercial and household air conditioners, the production method basically used is hot extrusion! And the production method used is generally a large-tonnage press (generally 2200T3600T) using a bar as a raw material to peel and extrude a number of micro-channel aluminum tubes (commonly known as one out 2, one out 3, one out 4, one Out 6, out of 8), this model has a good control of the temperature and extrusion force of the material, so that the crystal structure of the product structure is uniform and dense, the obtained product has high burst test pressure, can be manufactured with thin wall thickness, unit Flat tubes of zinc-aluminum sprayed with high-quality micro-channels with light length and light weight. At the same time, this manufacturing method has high production efficiency, and the manufacturing cost is greatly reduced compared with other manufacturing methods.

At present, 1050 H12 Zinc sprayed micro-channel aluminum tubes applied spraying zinc on the surface of micro-channel aluminum tubes. Melting spraying uses a DC low voltage and strong current arc. The high temperature and high heat of the arc melt the zinc as the electrode. Melt-jet arc spraying uses two sprayed zinc wires as consumable electrodes. When the two zinc wires are shorted to ignite the arc, the subsequent metal wires are continuously fed in to supplement the molten part to maintain the arc. Stable combustion. In order to maintain the stable combustion of the arc at the end of the zinc wire, on the one hand, an external air flow is required to separate the molten zinc from the end, on the other hand, it is necessary to establish a corresponding balance between the arc voltage, arc current, and wire feed speed.